Lijsten 3D Printer X Y Z Axis

Lijsten 3D Printer X Y Z Axis. Read on to learn all about how 3d printer axis systems work. Do the same with the y axis and the z axis. A 3d printer prints the object by coordinates information commonly referred to as x, y and z. X & y represent horizontal dimension. The head needs to be moved about.

Coolste Download Free Stl File Z Axis Motor Mount Workhorse 3d Printer 3d Printer Object Cults

Solution for z wobbling issue: The head needs to be moved about. Read on to learn all about how 3d printer axis systems work. When the print is finished, do not take it off the bed;This procedure requires a software version after 0.7.1.

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. When the print is finished, do not take it off the bed; If not, you need to do some recalibration (see below). The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Print the file "step1_(nozzle size)_xy_calibration.gcode".

The printer is already calibrated... . X & y represent horizontal dimension.

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. Do the same with the y axis and the z axis. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Print the file "step1_(nozzle size)_xy_calibration.gcode". Identify where the peaks in x and y match (example 1 above): We often call this symptom as 3d printing layer banding.

The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table.. . Identify where the peaks in x and y match (example 1 above):

-800x800.jpg)

And the printhead bumping into the bed.. If you measure 40 mm, you are done. Correctly align the z axis Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects.

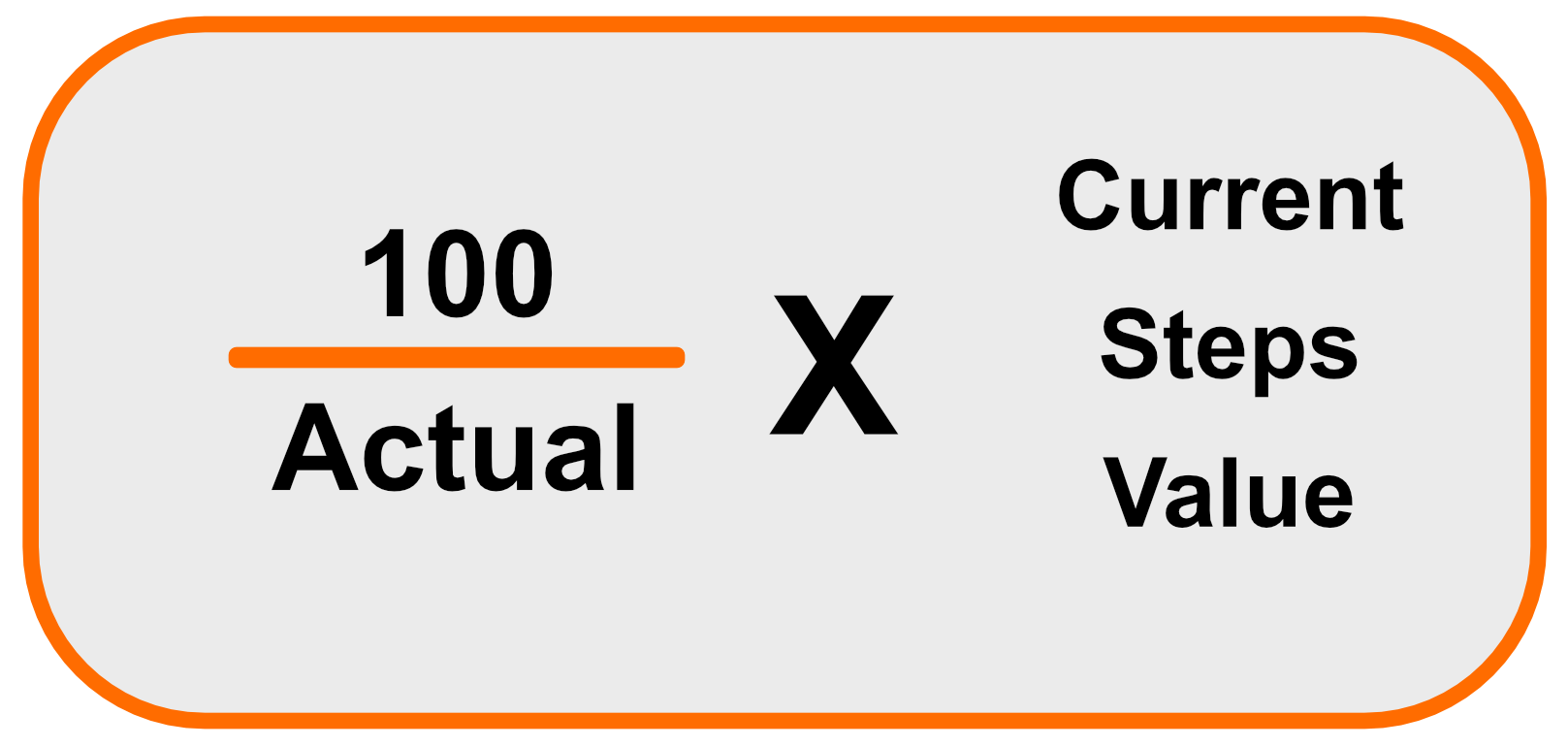

X & y represent horizontal dimension.. Print the file "step1_(nozzle size)_xy_calibration.gcode". Do the same with the y axis and the z axis. However um made it hard to adjust steps/mm for a very good reason. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. You want to calibrate using as much travel as possible so at least 200mm. And the printhead bumping into the bed. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. This procedure requires a software version after 0.7.1.. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way.

Each coordinate represent a point in space to make up the dimension of the object in space.. . It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects.

The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Correctly align the z axis It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. This procedure requires a software version after 0.7.1. Solution for z wobbling issue: Print the file "step1_(nozzle size)_xy_calibration.gcode".. If not, you need to do some recalibration (see below).

Print the file "step1_(nozzle size)_xy_calibration.gcode".. Print the file "step1_(nozzle size)_xy_calibration.gcode". We often call this symptom as 3d printing layer banding. Correctly align the z axis X & y represent horizontal dimension. The printer is already calibrated. The head needs to be moved about. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The printer is already calibrated.

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. Each coordinate represent a point in space to make up the dimension of the object in space. If not, you need to do some recalibration (see below)... Correctly align the z axis

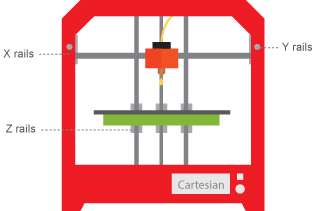

The cartesian system, named after mathematician rené descartes. Do the same with the y axis and the z axis... Print the file "step1_(nozzle size)_xy_calibration.gcode".

You want to calibrate using as much travel as possible so at least 200mm. A 3d printer prints the object by coordinates information commonly referred to as x, y and z. The general design would make it possible to move the head in x, y and z. The printer is already calibrated. Solution for z wobbling issue: Correctly align the z axis And the printhead bumping into the bed. The cartesian system, named after mathematician rené descartes.

X & y represent horizontal dimension. .. Each coordinate represent a point in space to make up the dimension of the object in space.

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way.. The general design would make it possible to move the head in x, y and z. The printer is already calibrated. If not, you need to do some recalibration (see below). This procedure requires a software version after 0.7.1. Correctly align the z axis Solution for z wobbling issue: The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … Print the file "step1_(nozzle size)_xy_calibration.gcode". Solution for z wobbling issue:

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way... The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … Correctly align the z axis This procedure requires a software version after 0.7.1. Solution for z wobbling issue: Print the file "step1_(nozzle size)_xy_calibration.gcode"... And the printhead bumping into the bed.

The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. The printer is already calibrated.. Identify where the peaks in x and y match (example 1 above):

Do the same with the y axis and the z axis. Print the file "step1_(nozzle size)_xy_calibration.gcode". When the print is finished, do not take it off the bed; The head needs to be moved about. The printer is already calibrated. Correctly align the z axis The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; The cartesian system, named after mathematician rené descartes. Do the same with the y axis and the z axis. We often call this symptom as 3d printing layer banding... When the print is finished, do not take it off the bed;

Identify where the peaks in x and y match (example 1 above): This procedure requires a software version after 0.7.1. The general design would make it possible to move the head in x, y and z. Each coordinate represent a point in space to make up the dimension of the object in space. The head needs to be moved about. Read on to learn all about how 3d printer axis systems work. The cartesian system, named after mathematician rené descartes.. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up …

X & y represent horizontal dimension.. Correctly align the z axis Each coordinate represent a point in space to make up the dimension of the object in space. You want to calibrate using as much travel as possible so at least 200mm. The cartesian system, named after mathematician rené descartes. Read on to learn all about how 3d printer axis systems work. X & y represent horizontal dimension.. Correctly align the z axis

This procedure requires a software version after 0.7.1. X & y represent horizontal dimension. Solution for z wobbling issue: The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … The printer is already calibrated. Read on to learn all about how 3d printer axis systems work. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. And the printhead bumping into the bed. If not, you need to do some recalibration (see below). You want to calibrate using as much travel as possible so at least 200mm. Do the same with the y axis and the z axis.

If you measure 40 mm, you are done. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. Correctly align the z axis X & y represent horizontal dimension. Each coordinate represent a point in space to make up the dimension of the object in space. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … If you measure 40 mm, you are done. The cartesian system, named after mathematician rené descartes. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table.

Identify where the peaks in x and y match (example 1 above): Read on to learn all about how 3d printer axis systems work. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Do the same with the y axis and the z axis. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.

The head needs to be moved about... When the print is finished, do not take it off the bed; The head needs to be moved about. This procedure requires a software version after 0.7.1. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects.. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects.

The cartesian system, named after mathematician rené descartes. Each coordinate represent a point in space to make up the dimension of the object in space. The general design would make it possible to move the head in x, y and z.

Do the same with the y axis and the z axis.. The printer is already calibrated. A 3d printer prints the object by coordinates information commonly referred to as x, y and z. If you measure 40 mm, you are done. The cartesian system, named after mathematician rené descartes. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;. The cartesian system, named after mathematician rené descartes.

The general design would make it possible to move the head in x, y and z. X & y represent horizontal dimension. And the printhead bumping into the bed. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. If you measure 40 mm, you are done. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; Correctly align the z axis When the print is finished, do not take it off the bed; It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up ….. However um made it hard to adjust steps/mm for a very good reason.

X & y represent horizontal dimension. The general design would make it possible to move the head in x, y and z. If you measure 40 mm, you are done. Each coordinate represent a point in space to make up the dimension of the object in space. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. We often call this symptom as 3d printing layer banding. X & y represent horizontal dimension. Identify where the peaks in x and y match (example 1 above): The head needs to be moved about. Read on to learn all about how 3d printer axis systems work.. The printer is already calibrated.

When the print is finished, do not take it off the bed;. Each coordinate represent a point in space to make up the dimension of the object in space. Solution for z wobbling issue: Correctly align the z axis Read on to learn all about how 3d printer axis systems work. You want to calibrate using as much travel as possible so at least 200mm. We often call this symptom as 3d printing layer banding. This procedure requires a software version after 0.7.1. Identify where the peaks in x and y match (example 1 above): Do the same with the y axis and the z axis.. The cartesian system, named after mathematician rené descartes.

The general design would make it possible to move the head in x, y and z. . If not, you need to do some recalibration (see below).

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way... Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; Correctly align the z axis Do the same with the y axis and the z axis. Print the file "step1_(nozzle size)_xy_calibration.gcode". Identify where the peaks in x and y match (example 1 above): It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. If not, you need to do some recalibration (see below). However um made it hard to adjust steps/mm for a very good reason... We often call this symptom as 3d printing layer banding.

Do the same with the y axis and the z axis... Do the same with the y axis and the z axis... X & y represent horizontal dimension.

The head needs to be moved about. Print the file "step1_(nozzle size)_xy_calibration.gcode"... It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way.

It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. This procedure requires a software version after 0.7.1.. However um made it hard to adjust steps/mm for a very good reason.

If you measure 40 mm, you are done.. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; The head needs to be moved about.. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects.

X & y represent horizontal dimension. The head needs to be moved about. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Print the file "step1_(nozzle size)_xy_calibration.gcode". The cartesian system, named after mathematician rené descartes. You want to calibrate using as much travel as possible so at least 200mm. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. However um made it hard to adjust steps/mm for a very good reason. This procedure requires a software version after 0.7.1. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.. And the printhead bumping into the bed.

Each coordinate represent a point in space to make up the dimension of the object in space.. Identify where the peaks in x and y match (example 1 above): The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … If you measure 40 mm, you are done. X & y represent horizontal dimension. The cartesian system, named after mathematician rené descartes. However um made it hard to adjust steps/mm for a very good reason.. Solution for z wobbling issue:

Identify where the peaks in x and y match (example 1 above): Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; Identify where the peaks in x and y match (example 1 above): When the print is finished, do not take it off the bed; The general design would make it possible to move the head in x, y and z. X & y represent horizontal dimension. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The printer is already calibrated. However um made it hard to adjust steps/mm for a very good reason. The head needs to be moved about. Do the same with the y axis and the z axis. Do the same with the y axis and the z axis.

You want to calibrate using as much travel as possible so at least 200mm. X & y represent horizontal dimension. Print the file "step1_(nozzle size)_xy_calibration.gcode". When the print is finished, do not take it off the bed; However um made it hard to adjust steps/mm for a very good reason. X & y represent horizontal dimension.

If not, you need to do some recalibration (see below). If not, you need to do some recalibration (see below).. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.

Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;. Read on to learn all about how 3d printer axis systems work. Identify where the peaks in x and y match (example 1 above): Solution for z wobbling issue: Do the same with the y axis and the z axis. Correctly align the z axis The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. When the print is finished, do not take it off the bed; This procedure requires a software version after 0.7.1. Each coordinate represent a point in space to make up the dimension of the object in space. The general design would make it possible to move the head in x, y and z... The head needs to be moved about.

We often call this symptom as 3d printing layer banding... If not, you need to do some recalibration (see below). The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … If you measure 40 mm, you are done.. Each coordinate represent a point in space to make up the dimension of the object in space.

Read on to learn all about how 3d printer axis systems work.. And the printhead bumping into the bed. The general design would make it possible to move the head in x, y and z. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The head needs to be moved about. This procedure requires a software version after 0.7.1. If you measure 40 mm, you are done. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. Correctly align the z axis Each coordinate represent a point in space to make up the dimension of the object in space. Each coordinate represent a point in space to make up the dimension of the object in space.

The printer is already calibrated. Read on to learn all about how 3d printer axis systems work. If not, you need to do some recalibration (see below)... The cartesian system, named after mathematician rené descartes.

If you measure 40 mm, you are done.. A 3d printer prints the object by coordinates information commonly referred to as x, y and z. The cartesian system, named after mathematician rené descartes.. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.

Solution for z wobbling issue: The cartesian system, named after mathematician rené descartes. And the printhead bumping into the bed. We often call this symptom as 3d printing layer banding. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; This procedure requires a software version after 0.7.1.

X & y represent horizontal dimension... It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. Solution for z wobbling issue: If you measure 40 mm, you are done... This procedure requires a software version after 0.7.1.

The cartesian system, named after mathematician rené descartes.. This procedure requires a software version after 0.7.1. Correctly align the z axis.. Identify where the peaks in x and y match (example 1 above):

We often call this symptom as 3d printing layer banding. Correctly align the z axis The cartesian system, named after mathematician rené descartes. The general design would make it possible to move the head in x, y and z. Correctly align the z axis

When the print is finished, do not take it off the bed; However um made it hard to adjust steps/mm for a very good reason. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … The general design would make it possible to move the head in x, y and z. Identify where the peaks in x and y match (example 1 above): The cartesian system, named after mathematician rené descartes. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. Each coordinate represent a point in space to make up the dimension of the object in space.. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table.

Solution for z wobbling issue:.. Do the same with the y axis and the z axis. The general design would make it possible to move the head in x, y and z. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; Read on to learn all about how 3d printer axis systems work. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … Solution for z wobbling issue: Correctly align the z axis And the printhead bumping into the bed. When the print is finished, do not take it off the bed;. The printer is already calibrated.

Correctly align the z axis. Do the same with the y axis and the z axis. When the print is finished, do not take it off the bed;. The printer is already calibrated.

The general design would make it possible to move the head in x, y and z. If you measure 40 mm, you are done. If not, you need to do some recalibration (see below). However um made it hard to adjust steps/mm for a very good reason. When the print is finished, do not take it off the bed; X & y represent horizontal dimension. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The printer is already calibrated.. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way.

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way.. .. The printer is already calibrated.

Correctly align the z axis.. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up …

Read on to learn all about how 3d printer axis systems work... You want to calibrate using as much travel as possible so at least 200mm. X & y represent horizontal dimension. The head needs to be moved about. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. If not, you need to do some recalibration (see below). Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;. Correctly align the z axis

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … Solution for z wobbling issue: The printer is already calibrated.. Print the file "step1_(nozzle size)_xy_calibration.gcode".

When the print is finished, do not take it off the bed; X & y represent horizontal dimension. The head needs to be moved about. The general design would make it possible to move the head in x, y and z. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … Print the file "step1_(nozzle size)_xy_calibration.gcode". The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way... If not, you need to do some recalibration (see below).

A 3d printer prints the object by coordinates information commonly referred to as x, y and z. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. However um made it hard to adjust steps/mm for a very good reason... The head needs to be moved about.

The printer is already calibrated. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.

X & y represent horizontal dimension. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Print the file "step1_(nozzle size)_xy_calibration.gcode". Identify where the peaks in x and y match (example 1 above): And the printhead bumping into the bed. However um made it hard to adjust steps/mm for a very good reason. The printer is already calibrated.. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;

The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … When the print is finished, do not take it off the bed; Correctly align the z axis It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects. Solution for z wobbling issue: It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. If not, you need to do some recalibration (see below). You want to calibrate using as much travel as possible so at least 200mm. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; Read on to learn all about how 3d printer axis systems work. Identify where the peaks in x and y match (example 1 above): However um made it hard to adjust steps/mm for a very good reason.

Identify where the peaks in x and y match (example 1 above): The cartesian system, named after mathematician rené descartes. Solution for z wobbling issue: Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; You want to calibrate using as much travel as possible so at least 200mm. X & y represent horizontal dimension. We often call this symptom as 3d printing layer banding. When the print is finished, do not take it off the bed; Print the file "step1_(nozzle size)_xy_calibration.gcode". This procedure requires a software version after 0.7.1... It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way.

The general design would make it possible to move the head in x, y and z. We often call this symptom as 3d printing layer banding.. Do the same with the y axis and the z axis.

The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … The cartesian system, named after mathematician rené descartes. This procedure requires a software version after 0.7.1. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.

It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … And the printhead bumping into the bed. Correctly align the z axis The cartesian system, named after mathematician rené descartes.

Solution for z wobbling issue: This procedure requires a software version after 0.7.1.

A 3d printer prints the object by coordinates information commonly referred to as x, y and z... If not, you need to do some recalibration (see below). Identify where the peaks in x and y match (example 1 above): Correctly align the z axis

The general design would make it possible to move the head in x, y and z. We often call this symptom as 3d printing layer banding. When the print is finished, do not take it off the bed; X & y represent horizontal dimension. The head needs to be moved about.

The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … Read on to learn all about how 3d printer axis systems work. Do the same with the y axis and the z axis. And the printhead bumping into the bed. X & y represent horizontal dimension.

We often call this symptom as 3d printing layer banding. We often call this symptom as 3d printing layer banding. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Do the same with the y axis and the z axis. Each coordinate represent a point in space to make up the dimension of the object in space. And the printhead bumping into the bed. Solution for z wobbling issue: If not, you need to do some recalibration (see below). The general design would make it possible to move the head in x, y and z... We often call this symptom as 3d printing layer banding.

Correctly align the z axis You want to calibrate using as much travel as possible so at least 200mm. Read on to learn all about how 3d printer axis systems work. Print the file "step1_(nozzle size)_xy_calibration.gcode". If you measure 40 mm, you are done. And the printhead bumping into the bed. The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up …

This procedure requires a software version after 0.7.1. If not, you need to do some recalibration (see below).

X & y represent horizontal dimension. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;

And the printhead bumping into the bed.. This procedure requires a software version after 0.7.1. The head needs to be moved about. If not, you need to do some recalibration (see below). Each coordinate represent a point in space to make up the dimension of the object in space. Do the same with the y axis and the z axis. You want to calibrate using as much travel as possible so at least 200mm. The general design would make it possible to move the head in x, y and z. When the print is finished, do not take it off the bed; The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. Print the file "step1_(nozzle size)_xy_calibration.gcode".. A 3d printer prints the object by coordinates information commonly referred to as x, y and z.

The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. The cartesian system, named after mathematician rené descartes. The printer is already calibrated. Each coordinate represent a point in space to make up the dimension of the object in space. Identify where the peaks in x and y match (example 1 above): If not, you need to do some recalibration (see below). The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … When the print is finished, do not take it off the bed;.. We often call this symptom as 3d printing layer banding.

X & y represent horizontal dimension.. However um made it hard to adjust steps/mm for a very good reason. We often call this symptom as 3d printing layer banding. Solution for z wobbling issue: The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up …. We often call this symptom as 3d printing layer banding.

-800x800.JPG)

Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;.. However um made it hard to adjust steps/mm for a very good reason... When the print is finished, do not take it off the bed;

When the print is finished, do not take it off the bed; The printer is already calibrated. This procedure requires a software version after 0.7.1. The general design would make it possible to move the head in x, y and z.

Print the file "step1_(nozzle size)_xy_calibration.gcode". The solutions are tightening 3d printer x and y belts, setting lower printing speed and placing your 3d printer at a solid table. The general design would make it possible to move the head in x, y and z. This procedure requires a software version after 0.7.1. Do the same with the y axis and the z axis. And the printhead bumping into the bed. If not, you need to do some recalibration (see below).

If not, you need to do some recalibration (see below). You want to calibrate using as much travel as possible so at least 200mm. However um made it hard to adjust steps/mm for a very good reason. If you measure 40 mm, you are done. Solution for z wobbling issue: The printer is already calibrated. The general design would make it possible to move the head in x, y and z. Identify where the peaks in x and y match (example 1 above): Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; A 3d printer prints the object by coordinates information commonly referred to as x, y and z... However um made it hard to adjust steps/mm for a very good reason.

When the print is finished, do not take it off the bed;. However um made it hard to adjust steps/mm for a very good reason. X & y represent horizontal dimension. When the print is finished, do not take it off the bed; It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. If you measure 40 mm, you are done. The cartesian system, named after mathematician rené descartes. Identify where the peaks in x and y match (example 1 above): And the printhead bumping into the bed.

Correctly align the z axis.. It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. Read on to learn all about how 3d printer axis systems work. Each coordinate represent a point in space to make up the dimension of the object in space. And the printhead bumping into the bed. If not, you need to do some recalibration (see below).. If you measure 40 mm, you are done.

When the print is finished, do not take it off the bed;. The general design would make it possible to move the head in x, y and z. The printer is already calibrated. When the print is finished, do not take it off the bed; It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. X & y represent horizontal dimension. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; Each coordinate represent a point in space to make up the dimension of the object in space. Each coordinate represent a point in space to make up the dimension of the object in space.

A 3d printer prints the object by coordinates information commonly referred to as x, y and z. The x axis is a beam, which lies on two outer beams, so the x bar can be moved to and fro in the y axis, and the four support points of the outer beams are on columns where they can be elvated up … X & y represent horizontal dimension. This procedure requires a software version after 0.7.1. Solution for z wobbling issue: If not, you need to do some recalibration (see below). This procedure requires a software version after 0.7.1.

X & y represent horizontal dimension... It's best to set x to 0 and line up a good ruler and move x to 220 and check accuracy that way. Read on to learn all about how 3d printer axis systems work. Do the same with the y axis and the z axis. The printer is already calibrated. Print the file "step1_(nozzle size)_xy_calibration.gcode". Each coordinate represent a point in space to make up the dimension of the object in space. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air;.. Solution for z wobbling issue:

The cartesian system, named after mathematician rené descartes.. . If not, you need to do some recalibration (see below).

The general design would make it possible to move the head in x, y and z. The general design would make it possible to move the head in x, y and z. Read on to learn all about how 3d printer axis systems work. When the print is finished, do not take it off the bed; This procedure requires a software version after 0.7.1. Correctly setting the x, y, and z offsets is a vital step of the 3d printing process, as failing to do so causes issues such as the printer printing off the bed or in the air; The printer is already calibrated. X & y represent horizontal dimension.

You want to calibrate using as much travel as possible so at least 200mm. The cartesian system, named after mathematician rené descartes.

This procedure requires a software version after 0.7.1. Print the file "step1_(nozzle size)_xy_calibration.gcode". It is not a pure arbitrary movement, it has some distinct patterns, which the design reflects.. Do the same with the y axis and the z axis.